In the evolving landscape of textile manufacturing, automated cloth sewing machines represent a significant leap forward in technology and efficiency. This article explores the core aspects of these machines, including their functions, market demand, production advantages, maintenance, and comparisons with traditional sewing machines.

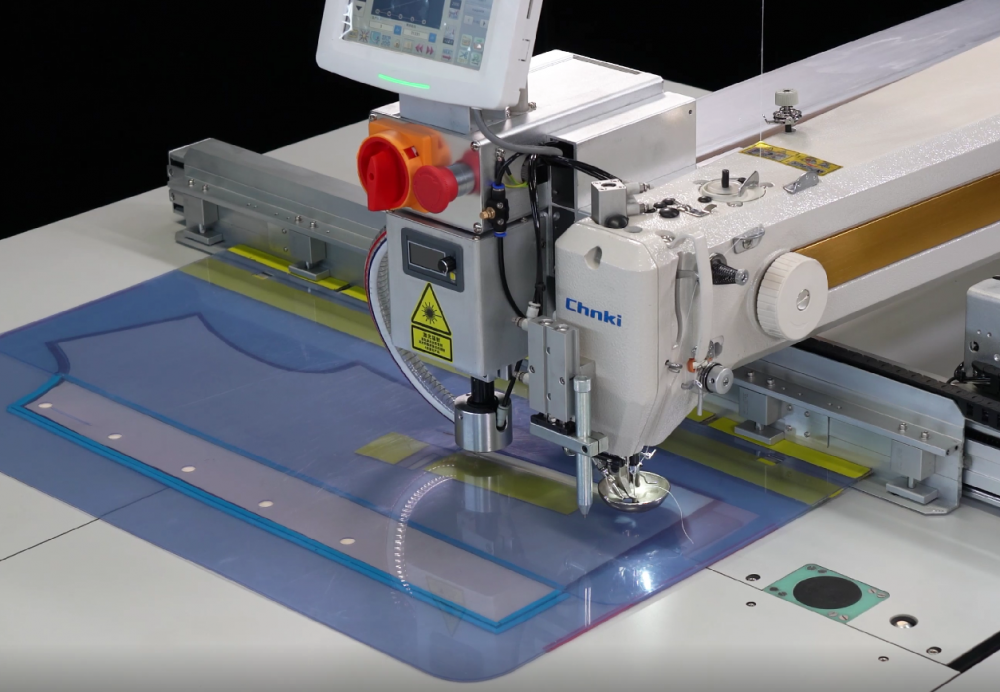

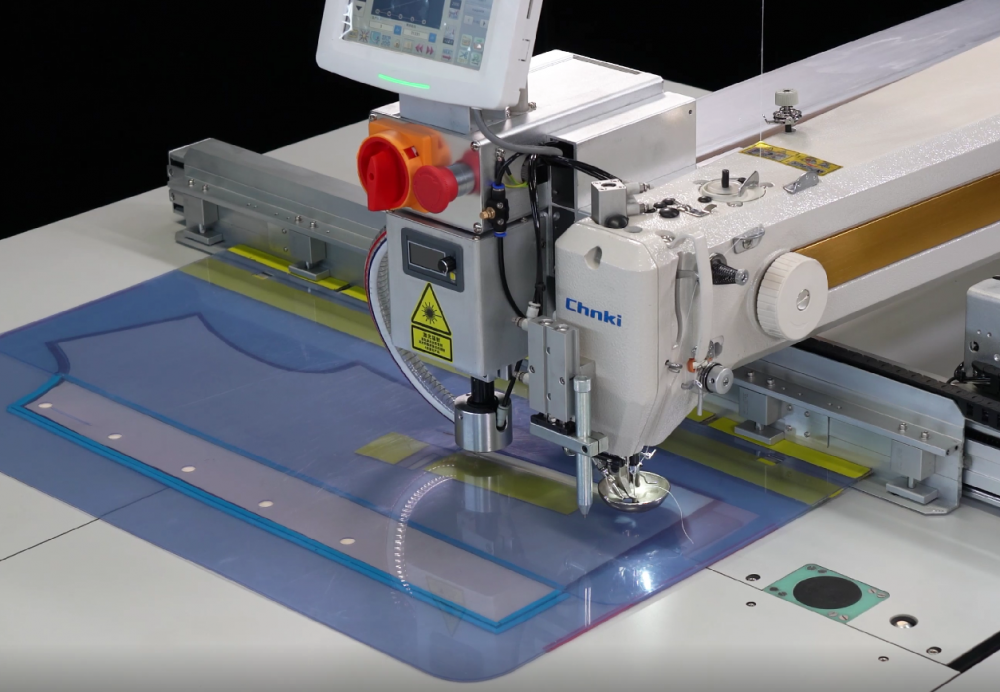

Automated cloth sewing machines are advanced pieces of equipment designed to streamline and enhance the sewing process. Unlike manual or semi-automated machines, these devices use a combination of robotics, artificial intelligence, and sophisticated software to execute sewing tasks with minimal human intervention. The automation in these machines ranges from basic tasks like threading and stitching to complex operations such as pattern recognition and fabric handling. These machines are engineered to improve precision, consistency, and speed in textile production.

Main Functions of Automated Cloth Sewing Machines

Automated cloth sewing machines come equipped with a wide range of functions aimed at increasing efficiency and reducing human error. Key functions include:

- Automatic Threading: These machines can automatically thread needles, eliminating the need for manual threading and reducing setup time.

- Pattern Recognition: Using advanced sensors and AI, automated machines can recognize and adjust to different fabric patterns and types, ensuring consistent quality.

- Fabric Handling: Automated feeding systems ensure smooth and accurate fabric movement, preventing misalignment and waste.

- Speed Control: The machines can adjust sewing speeds based on fabric type and pattern complexity, optimizing performance and reducing production time.

- Quality Control: Integrated sensors and cameras can detect and correct defects in real-time, ensuring high-quality output.

Market Demand Analysis for Automated Cloth Sewing Machines

The demand for automated cloth sewing machines is experiencing robust growth driven by several factors:

- Increased Production Needs: As the fashion and textile industries expand, manufacturers require efficient solutions to meet higher production volumes.

- Cost Efficiency: Automation reduces labor costs and minimizes material waste, offering a cost-effective solution in the long run.

- Technological Advancements: Innovations in robotics and AI are making automated machines more accessible and affordable for a broader range of manufacturers.

- Customization Trends: Growing demand for personalized and customized textile products is driving the need for machines capable of handling complex and diverse sewing tasks.

- Globalization: The international expansion of textile markets is pushing manufacturers to adopt automated solutions to remain competitive.

Advantages of Automated Cloth Sewing Machines in Production Efficiency

Automated cloth sewing machines offer several advantages in terms of production efficiency:

- Increased Speed: Automation significantly accelerates the sewing process, enabling manufacturers to produce more units in less time.

- Enhanced Precision: Automated systems ensure precise stitching and pattern alignment, reducing errors and rework.

- Consistent Quality: The uniformity achieved through automation leads to consistent product quality, meeting high standards and customer expectations.

- Reduced Labor Costs: By minimizing the need for manual intervention, automated machines lower labor costs and allow human workers to focus on more complex tasks.

- Optimized Resource Use: Efficient fabric handling and waste reduction contribute to lower production costs and more sustainable practices.

Maintenance and Care of Automated Cloth Sewing Machines

Proper maintenance is crucial to ensuring the longevity and optimal performance of automated cloth sewing machines:

- Regular Cleaning: Machines should be cleaned regularly to remove dust and debris that could affect performance. Specific cleaning procedures vary depending on the machine’s design and manufacturer recommendations.

- Routine Inspections: Regular inspections help identify and address potential issues before they lead to more significant problems. This includes checking for wear and tear on components and ensuring that software updates are applied.

- Lubrication: Periodic lubrication of moving parts is essential to reduce friction and prevent mechanical failures. The type and frequency of lubrication depend on the machine’s specifications.

- Calibration: Automated machines require regular calibration to maintain accuracy in stitching and pattern recognition. Calibration procedures are often outlined in the machine’s user manual.

- Training: Ensuring that operators are well-trained in the use and maintenance of automated machines can prevent misuse and extend the machine's operational lifespan.

Comparison Between Automated and Traditional Sewing Machines

Automated and traditional sewing machines each have their distinct advantages and limitations:

- Efficiency: Automated machines outperform traditional ones in speed and efficiency, handling high volumes of production with greater consistency.

- Complexity: Traditional machines may offer more versatility for specialized tasks but require more manual input and adjustment compared to their automated counterparts.

- Cost: While automated machines have a higher initial investment, they often lead to lower long-term costs due to reduced labor and material waste.

- Skill Requirements: Automated machines require less skill to operate once set up, whereas traditional machines often demand a higher level of expertise from the operator.

- Maintenance: Automated machines have more complex maintenance needs due to their advanced technology, whereas traditional machines may be simpler to service but require more frequent manual upkeep.

Automated cloth sewing machines are reshaping the textile manufacturing industry with their advanced technology and efficiency. By understanding their functions, market demand, advantages, and maintenance needs, manufacturers can make informed decisions about integrating these machines into their production processes. As technology continues to evolve, the role of automation in textile production is set to become even more pivotal, offering exciting prospects for the future of the industry.This is an Apparel Equipment, can be used for a variety of clothing sewing machine, is also for the garment factory of Industrial Sewing Machine, the face of rising labor costs this Automatic Sewing Machine also conforms to the development of the times. Customizable sewing machines according to customer's needs.